Start Your Search Here

Protect your seat covers with CORDURA® Fabrics.

Northwest Seat Covers - Fabric Comparison Guide

| Series Fabric |

Cordura® Classc-500D |

Cordura® Pro-Gard™ |

OEM™ Carbon Fiber |

OEM™ OEM-Classic |

OEM™ Cool Sport |

Heavy Duty Dyna-Flex™ |

Heavy Duty Ballistic |

Heavy Duty Saddle Blanket |

Heavy Duty Vinyl |

Neoprene Neo-Ultra™ |

Neoprene NeoSupreme |

Camo KT/MO/RT/MS/NX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Price | $$$ | $$$ | $$$ | $ | $$ | $$ | $$$ | $ | $ | $$ | $$ | $$$ |

| Water Resistance | Best | Best | Very Good | OK | N/A | Best | Very Good | N/A | Best | Best | OK | Very Good |

| Fabric Strength | Best | Best | Very Good | Very Good | Good | Very Good | Very Good | Very Good | Good | Good | Good | Very Good |

| Wear Resistance | Best | Best | Very Good | Very Good | Very Good | Very Good | Good | Best | Best | Good | Good | Very Good |

| Soft Touch | Good | Best | Very Good | Good | Best | Good | Good | N/A | Good | Best | Very Good | Good |

| Snag Resistant | Best | Best | Very Good | Very Good | Very Good | Very Good | Very Good | N/A | Best | Very Good | Very Good | Very Good |

| Breathability - Ventilated | N/A | N/A | Good | Good | Best | Good | Good | Very Good | N/A | N/A | Good | Good |

| Stain Resistant | Best | Good | Very Good | Good | Good | Good | Very Good | Best | Very Good | Good | Good | Very Good |

| Care - Machine or Hand | Machine | Machine | Machine | Machine | Machine | Machine | Machine | Hand | Hand | Hand | Hand | Machine |

| Compatible - Heated Seats | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Compatible - Ventilated Seats | No | No | No | No | Yes | No | No | Yes | No | No | No | No |

CORDURA® SEAT COVERS - NYCO - PREMIUM WATERPROOF FABRIC SEAT COVERS

The teams from Cordura, Northwest and their Authorized Fabric Mill worked together to develop a new version of the award winning CORDURA® NYCO Fabric. The popularity of Carhartt Seat Covers with its basic cotton canvas style fabric, inspired the Northwest Team to introduce CORDURA® seat cover with improved performance compared to the generic cotton duck weave material.

Having previously worked with CORDURA® to create an advanced version of the Classic 500 Denier Nylon fabric, we were confident that we could achieve the same excellent results for a dynamically improved double woven cotton waterproof seat cover fabric.

We established a performance benchmark by physically testing and documenting performance results. With that, we were able to determine the strengths and weaknesses of a regular cotton duck fabric with a DWR top-coating and PU under-coating.

Choose CORDURA® Seat Covers

Problem #1

The competitor's cotton duck fabric is bumpy and roughly textured. Making it uncomfortable to sit on for long periods of time, especially when it embosses that textured pattern onto your legs when you're wearing shorts.

Solution #1

We selected a compressed basket weave design that offered a nice soft feel, was comfortable to sit on and promoted top surface air circulation. Imagine your favorite pair of denim jeans, this is the type of fabric that would be super comfortable for a road trip or weekend getaway while also standing up to the rigors of the workweek.

Problem #2

Cotton Duck customer reviews express a lot of dissatisfaction with the Install, Fit and Production Time of the seat covers.

Solution #2

Working with the CORDURA® Fabric Team, we knew that their expertise would be invaluable when evaluating fabric possibilities. We wanted to create CORDURA® Seat Covers that would be install-friendly, fit very well, and offer superior protection.

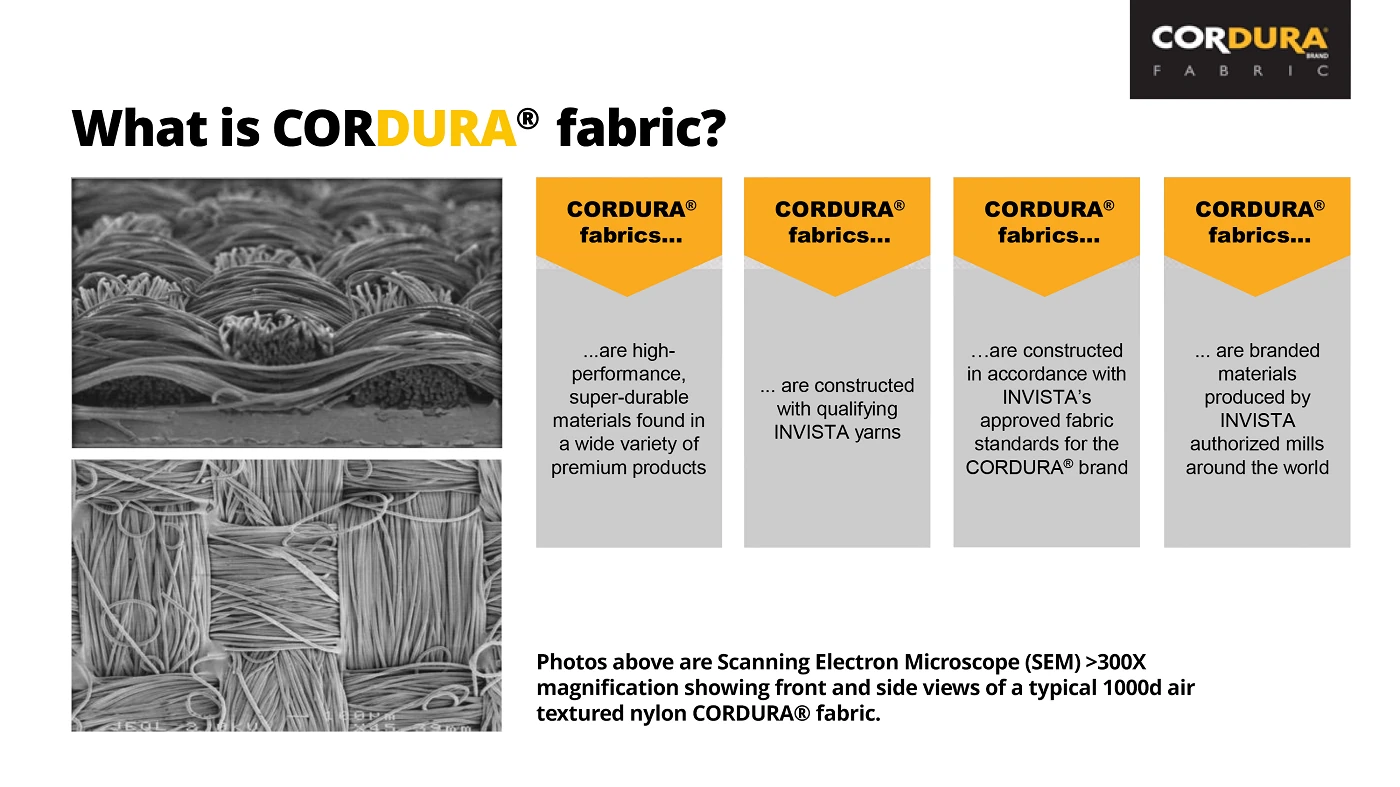

To do so, we selected the Classic 500D and NYCO fabrics, but with our own twist. We enhanced the design of the weave and added another process, so the fabric would not be bumpy. We also incorporated a special dynamic yarn that reduced installation time by 20% and enhanced the appearance of the seat covers after a successful install experience … and yes, both exclusive fabrics are 100% waterproof! To elevate performance value, all CORDURA® Seat Covers incorporate Advanced 6,6 High Tenacity Air Jet Textured Nylon. Simply put, the fabrics are strong and the Nylon Cotton blend is 300% stronger than generic cotton fabrics.

Production time has never been an issue with Northwest Seat Covers because we're Industry Leaders in turning orders around in 3-5 business days - for custom made, it just doesn't get much better than that!

Problem #3

The competitor's cotton duck fabric was mildly effective at providing some water resistance but failed to offer high performance waterproof protection. During test trials, the cotton duck fabric was exposed to moderate rain, and we even spilled a soft drink on the cotton duck seat cover. Within seconds both the rainwater and soft drink started to penetrate and soak completely through the cotton duck fabric.

Solution #3

Northwest Seat Covers has its headquarters in the Pacific Northwest, so we know rain. We discovered early that high quality waterproof seat covers would be a must-have. When we started expanding our fabric selection, we included advanced waterproof protection and made sure that Gore-Tex style technology would be the backbone for our exclusive fabric collection. Today, Northwest has the largest collection of waterproof fabrics in the industry, including the Classic 500D & NYCO fabric that is used to create CORDURA® Seat Covers.

Waterproof CORDURA® Seat Covers vs. Water Resistant Canvas Seat Covers

The competitor's fabric appears to be a 10oz generic cotton duck canvas with a water-resistant protective spray on top of the fabric. As anyone who has ever bought a ski jacket can tell you, once the top coating of water repellant protection rubs off - you lose the water resistance. Northwest seat cover customers receive Premium Value when they purchase our Pro-Gard™ CORDURA® Seat Covers. Pro-Gard™ protection highlights include 3X waterproof technology, fabric strength that is 300% stronger than generic cotton canvas seat covers. This ensures your original seats are protected by 1. DWR Topcoat, 2. Polyurethane (PU) Undercoating, and 3. Our Gore-Tex style liquid barrier for any spilled liquids and will perform at the highest level - CORDURA® USA!

Summary

Pro-Gard™ Seat Covers were designed to be an alternative

to Carhartt Seat Covers.

It came down to CORDURA® Advanced Fabrics vs. Generic cotton duck fabric. We welcomed the award-winning global brand simply because it was a champion of

durability and high quality performance. To successfully do that, we enlisted the expertise of the folks at CORDURA® and their knowledge supplying large global

brands such as Ariat®, The North Face®, Filson®, Dickies Pro™, Dovetail Workwear®, the U.S. Military and more. The performance metrics we used for our

CORDURA® Seat Covers included waterproof technology, resilience to abrasion, comfort, fit, and ease of installation. These benchmarks give customers, who are

in the market for authentic cotton duck canvas seat covers, a worthy alternative to consider. Whether it's a treat for yourself or a gift for someone else,

our CORDURA® Seat Covers are guaranteed to meet the highest standards for durability and functionality, equivalent to military-grade performance!

Durability

CORDURA® fabric's high-quality structure and strong fibers allow it to excel in durability tests like the Wyzenbeek test. Through simulated abrasive actions, CORDURA® demonstrates remarkable resilience, making it a preferred choice for car and truck seat covers. Its capacity to withstand wear and tear ensures these covers last longer while retaining their visual appeal, offering an ideal balance of function and style.

UV Protection

In crafting our CORDURA® seat covers, UV light protection is of paramount importance. Following thorough testing, we employ a grade 3.5 UV protective coating, ensuring up to 200 hours of protection and significantly slowing the fabric fading process. While grade 1 coatings provide a natural feel but minimal protection and grade 5 coatings yield excellent protection but a stiff fabric, our chosen grade 3.5 offers a balance. This guarantees CORDURA® seat covers retain color and durability without sacrificing comfort.

Flammability & Safety

Flammability is a critical factor in our CORDURA® seat covers. The CORDURA® fabrics are treated with a Fire-Resistant (FR) coating, meeting either the FMVSS302 (Federal Motor Vehicle Safety Standard) or CPAI 84 Sections 5 and 6, depending on the fabric style. This ensures a high level of safety against fire hazards.

Waterproof

Waterproofing is another vital characteristic of our CORDURA® seat covers. Most fabrics we use are either highly water-repellent or entirely waterproof. However, over time and with regular use, the fabric's water-repelling effectiveness may lose its effectiveness. This can be restored by applying Scotchgard to our O.E fabrics or a DWR (Durable Water Repellent) to our other types.

HD Designs

Advancements in technology have revolutionized fabric possibilities, evident in our range of camouflage fabrics such as Realtree, Mossy Oak, and Moonshine. Producing these intricate camo seat cover patterns necessitates up to 10 screens. Our fabrics stand out due to the superior image quality achieved through heat transfer paper on durable 600 denier polyester fabrics, enhancing the visual appeal of our CORDURA® seat covers.

Reviews: See What Our Customers Have to Say

Average rating: 323 reviews

-

Paul

Whitehorse , YT

Received the covers in less than a week and they fit perfectlyNeeded new covers for my 99 Super Duty and found NW. They had the design I needed and their turnaround was very fast. Received the covers in less than a week and they fit perfectly. Easy install, great materials and the price was very reasonable for the package. And made in Canada too! Highly recommended NW.

-

Jerry Bruske

Custer, WI

When I received these seat covers I was VERY PLEASE with the quality and looks of them...When I received these seat covers I was VERY PLEASE with the quality and looks of them.... and even MORE SO after I installed them in my 2020 Chevrolet 2500 HD Double Cab. They were a perfect snug fit! Definitely will keep Northwest Seat Covers in mind for my next seat cover order.

-

Dawn Reilly

St. Clair Shores, MI

I didn’t know how essential seat covers were until I got my Northwest Seat Covers.I didn’t know how essential seat covers were until I got my Northwest Seat Covers. As a professional sailor, I now can jump into my car after the gym without worry or even in full foul weather gear after racing offshore. They fit perfectly and are comfortable in all extremes.

-

Stephanie Gordon

Columbus, OH

I saw your waterproof video and that was enough to convince me.I drive the neighborhood kids to soccer practice in our Tahoe, so I wanted seat covers for the 2nd and 3rd row seats. I saw your waterproof video and that was enough to convince me. Bought a couple of Pro-Gard seat covers and am very pleased with the installed product.