Dyna-Flex™ and Cordura

How similar are they?

History of Denier

Denier is a weight measurement that the textile industry has been using since the early 15th century when Charles VI, Charles VII and Louis XI ruled France. Its origin can be partly derived from the word Denarius which was an ancient Roman silver coin worth about 1 penny or a day's wages back in 211 BC. In today's value, it's worth about $3.75 USD (2018).

It is a reference to a small medieval French Silver coin which weighed about 1.2 grams. This weight was then applied to the weight of silk, where 9,000 linear meters of silk equals 1.0 gram or 1.0 Denier. In other words, a 9,000-meter strand of yarn from our 600 Denier Dyna-Flex™ fabric, weighs 600 grams or 600 Deniers.

9,000 meters of a single yarn of Cordura 500 D equals 500 grams or 500 Denier Rating.

9,000 meters of a single yarn of Cordura 1,000 D equals 1,000 grams or 1,000 Denier Rating.

Simply put, textile materials are constructed using Single Fibers that are grouped or twisted; these fibers are much stronger when combined. It's the idea that there is strength in numbers, one fiber vs. 100 fibers working together. (See Photo)

History of Polyester Fabrics

Dupont was established in 1802, by a French-American Éleuthère Irénée du Pont de Nemours in Wilmington, Delaware.

In 1926, DuPont began research on synthetic fibers and in the late 1930s, Wallace Hume Carothers discovered Polyester plastic, but a group of British scientists from the International General Electric Company, expanded on the research and patented the first commercial polyester fibre in 1941 which they called Terylene (Dacron) or Polyethylene Terephthalate (PET) which was equal to or better than nylon for toughness and resilience.

Today, PET is commonly used for food packaging such as peanut butter or strawberry baskets or detergent containers, beverage bottles or dishwashing soap etc.

To make polyester fibers, the PET plastic is heated and forced through little spinnerets into fibers (a spinneret is like an industrial showerhead)

The fibers are stretched to five times their length and combined into yarn and then woven or knit into polyester fabrics.

Dyna-Flex™ Seat Covers vs. Cordura

Everyone wants the best and brightest, but at an affordable price. Cordura Nylon is a good material, but it's pricey. The best competitive fabric is polyester and when it comes to performance, they are almost on par with one another. In a series of tests Nylon will perform better when it comes to absolute fiber strength and abrasion, but on the other hand Polyester is very tough with strong UV Light Anti-Fading and much lower risk of dye transfer onto your original seats.

Northwest Seat Cover patterns can be used with either Cordura Nylon or DuPont's Polyester; either way the fit will be great. There are slight differences in fabric performance, but a big difference when you Add-to-Cart. Like we said, everyone may want a Lamborghini Urus or a Bentley Bentayga SUV, but most of us are probably driving Explorers or RAV4s - It has to fit the budget.

How Tough is Dyna-Flex™ Material?

We used to use Genuine OEM materials from Ford, Chevrolet, Ram etc., for 100% of our seat cover fabric needs. When industry cyclical changes began to affect our supply chain, we started down the path to develop our own materials.

We needed a heavy-duty fabric that was tough enough to withstand the wear and tear that a frequent-stop delivery driver could do to the seats.

The most versatile fabric that we could think of was the 600 Denier Polyester material, but it would require a bit of engineering to bring the fabric up to OEM type specifications.

How we upgraded a traditional 600 Denier material to reflect OEM Style Standards:

- We wanted a higher than normal abrasion rating, so we increased the density of the fibers and the tightness of the weave. This would increase stability support to ensure the material did not easily move or separate from the pack and keep everything tight.

- Increased Comfort was achieved by working with the Specialty Division of one of the largest OEM laminators for automotive seat cover fabrics in North America. Working with the Operations Manager, we were able to secure a foam backing with just enough loft and comfort to provide some body to the normally flat 600D fabric.

- Dyna-Flex™ Seat Covers had to include levels of waterproofing. This was accomplished by adding 2 barriers of water protection. The first barrier is a coating of DWR (Durable Water Repellent) that is sprayed on top of the surface material. This is the same type of DWR that they use for Patagonia or Columbia outerwear.

The second barrier is located directly under the top surface fabric. This not only secures the material fibers in place, but also provides an additional layer of anti-water penetration, so that first layer of fabric includes double the protection.

Are Dyna-Flex™ Seat Covers a good fit with Heavy Industry?

It used to be that the best match for heavy-duty seat covers was an old saddle blanket fabric that was quite popular in the 1970s and 1980s.

It was the same type of material that mom would use as a scatter rug in front of the sink; a bunch of multi-color big woven fibers.

Well, times have changed, and the quality customers expect has changed as well. Old horse blanket style materials may look and feel tough, but that's it - they only look and feel tough.

Advancements in Textile Technology have introduced new ways of combining the best of different materials and incorporating them into Today's Performance fabrics.

So when someone asks whether an Dyna-Flex™ seat cover would be a good fit for heavy industry; the answer is - Yes! It took years of convincing, but we persistently demonstrated that Northwest's recommended solution to use Dyna-Flex™ instead of Saddle Blanket, paid off for everyone. A large portion of our fleet operators now insist on ordering Dyna-Flex™ seat covers exclusively. They fit well, look great and provide all of the protection of premium seat covers, but at a better price.

How well does Dyna-Flex™ material hold up to Pets?

When we were developing a Rear Seat Cover for 2nd and 3rd row back seats, we wanted, durability, strong wear resistance, waterproofing and puncture resistance.

The most comfortable material that checked all of those boxes was Dyna-Flex™ 600 Denier Polyester. The material is not stiff and is fairly pliable, it has also become a heavy industry favorite for wear and durability, it provides excellent waterproofing and can withstand the weight and pressure from your dog's nails.

The Truth about Material Construction

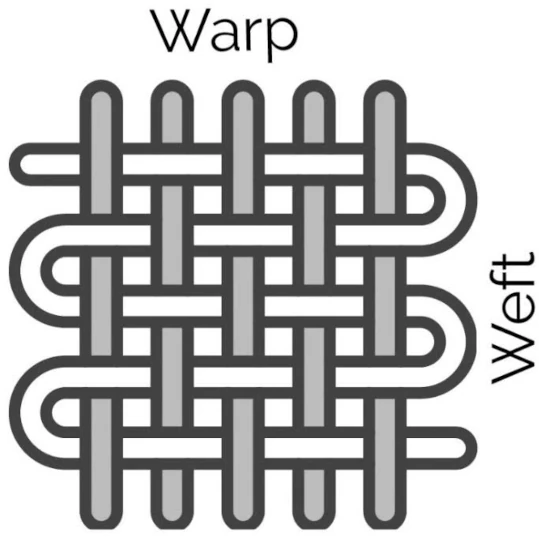

Woven fabrics are rather simple; they feature Warp and Weft components. Warp yarns run up and down the material, while Weft yarns go side to side.

Fact

Northwest's Dyna-Flex™ Seat Covers offer full value with no punches pulled. The construction of our Dyna-Flex™ material features a 45 Thread Count with a 600 Denier Warp and 600 Denier Weft construction. When Northwest offers 600D materials, it genuinely is a 600 Denier material.

Fiction

It's easy for companies to claim that they use 600 Denier materials, but are they really? It's only half the story because there may use 600D fibers in the warp part of the construction, but only 300 Denier in the Weft.

On top of that, how many yarns are they using in the warp and weft? Competing products may use a 35-40 Thread Count (TC) and charge you full price; that's not honest and not fair.

Summary

Northwest Seat Covers are developed by working very closely with the textile engineers within our supply chain. Remember, our background experience was with OEM Automotive Fabrics manufacturers like Guilford Mills, Lear and Collins & Aikman etc.

At Northwest we understand the type of specifications that are required to develop the best performing materials in their class.

Trust our team of Designers and Textile Engineers to provide you with the best-in-class solutions for your seating protection needs.